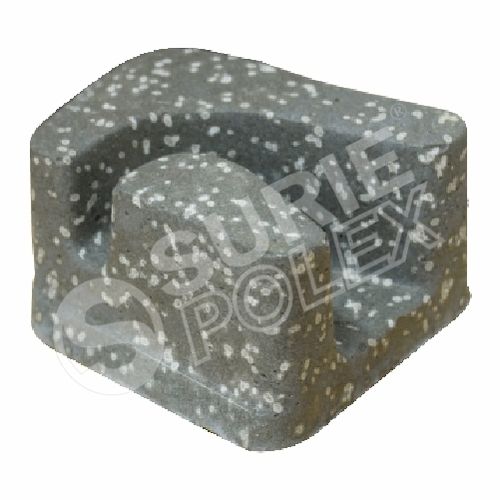

Marble Stone Batti

MOQ : 1 Piece

Marble Stone Batti Specification

- Toughness

- High, suitable for polishing and grinding

- Shape

- Casani

- Hardness

- Medium to High

- Backing

- Solid stone base

- Grain Type

- Abrasive Grain

- Bonding

- Resin Bonded

- Chemical Composition

- Marble stone with synthetic resin and abrasive components

- Material

- Synthetic Resin Bonded

- Type

- Marble Stone Batti

- Grain Sizes

- Available in various grit sizes as per requirement

- Strips Size

- Standard and custom sizes available

- Density

- High

- Application

- Used for floor polishing, grinding and finishing of stone surfaces

- Water Absorption

- Low

- Thickness

- Varies as per specification

- Durability

- Long-lasting

- Color

- Natural marble color, may vary

- Surface Finish

- Smooth and glossy

- Heat Resistance

- Good

Marble Stone Batti Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- New Delhi,India

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 3-7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- We use carton boxes for packaging. Wooden crate packaging is at extra cost.

- Main Export Market(s)

- North America, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia

- Main Domestic Market

- All India

About Marble Stone Batti

Specially formulated resin is used with the finest graded silicon carbide made in our captive micron processing plant leading to high productivity and maximum gloss. lowest cost per square meter.Superior Surface Finish

The Marble Stone Batti is engineered to deliver a smooth, glossy finish to marble and similar stone surfaces. Its combination of high-density marble and synthetic resin bonding ensures precise grinding and enhanced shine, making it a preferred material for floor polishing and stone finishing applications.

Versatile Sizing Options

With availability in various grit sizes and strip dimensions, Marble Stone Batti caters to both standardized and custom floor polishing needs. This flexibility allows users to select the optimal tool for specific surface requirements, streamlining both industrial and commercial projects across India.

FAQs of Marble Stone Batti:

Q: How is Marble Stone Batti used for polishing marble floors?

A: To polish marble floors, the Marble Stone Batti is attached to a floor-polishing machine where its abrasive grains smooth and refine the stone surface. Various grit sizes are available, enabling users to select finer or coarser strips based on the desired finish and process stage.Q: What benefits does the synthetic resin bonded structure provide?

A: The synthetic resin bonded structure enhances the toughness and durability of the Marble Stone Batti, improving performance during extended grinding and polishing tasks. It provides reliable bonding for abrasive grains, resulting in long-lasting usability and consistent finishing quality.Q: When should I choose custom strip sizes for my project?

A: Custom strip sizes are suitable when your project requires specific dimensions that differ from standard options. This flexibility allows for optimal fit and efficient polishing, especially in non-traditional or uniquely shaped stone surfaces.Q: Where can I purchase Marble Stone Batti in India?

A: You can obtain Marble Stone Batti from various distributors, exporters, importers, manufacturers, retailers, suppliers, traders, and wholesalers across India, ensuring availability for both large-scale industries and individual contractors.Q: What is the process for achieving a smooth and glossy finish using Marble Stone Batti?

A: Begin by selecting the appropriate grit size for your desired finish. Gradually work through coarser to finer grits with the floor-polishing machine, ensuring that each step is thorough. The abrasive grains and resin bond effectively polish and gloss the marble surface.Q: Why is low water absorption and high heat resistance important for Marble Stone Batti?

A: Low water absorption prevents damage and degradation during wet grinding, while high heat resistance allows prolonged usage without affecting performance or structural integrity, making Marble Stone Batti ideal for demanding polishing processes.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Conventional Polishing Abrasives Mag & Syn Category

Chamfering Marble Polishing Abrasive

Price 92.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Magnesite Bonded

Shape : CRK Chamfering

Synthetic Marble Poilsihing Abrasive

Price 132.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Synthetic Resin Bonded

Shape : Butterfly

Frankfurt Magnesite Abrasive

Price 85.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Magnesite Bonded

Shape : Frankfurt

Triangle Magnesite Marble Polishing Abrasive

Price 64.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Magnesite Bonded

Shape : TTriangle

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free