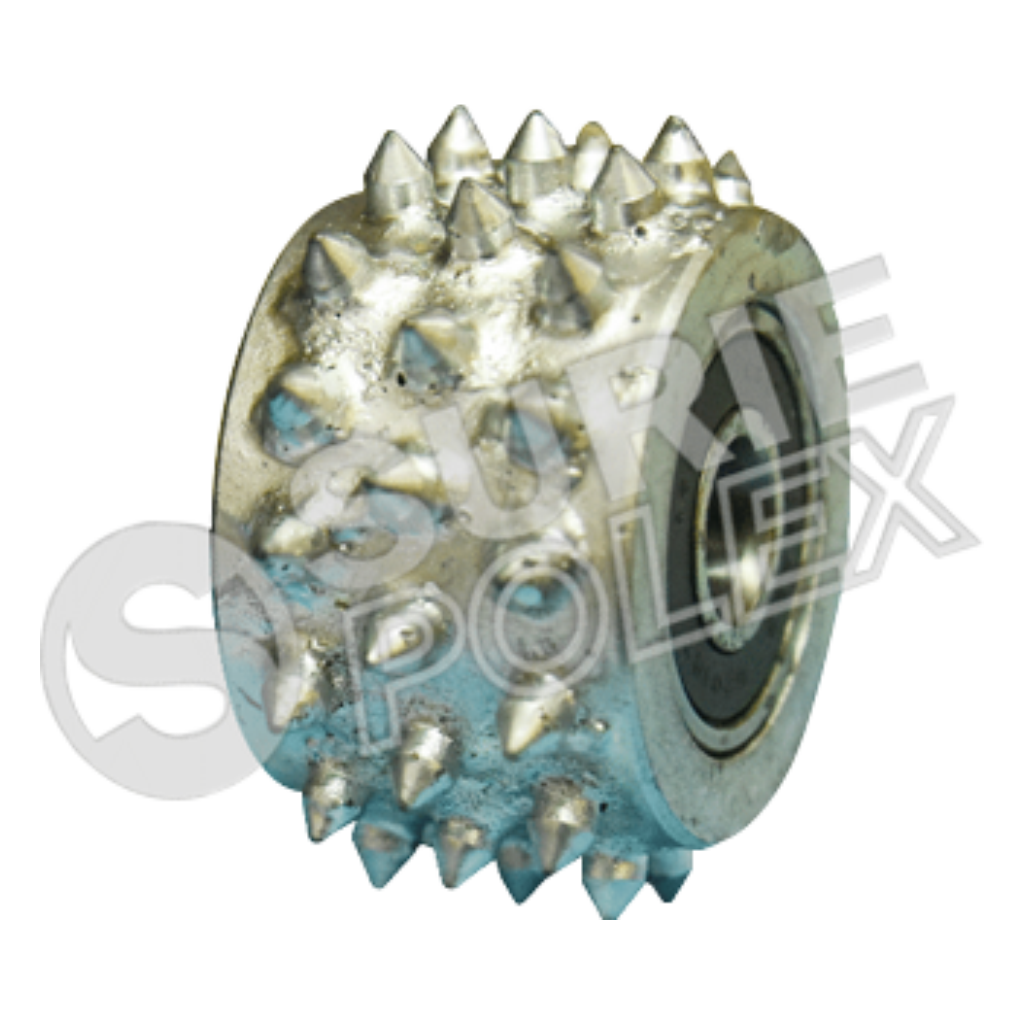

Diamond Bush Hammer

MOQ : 1 Piece

Diamond Bush Hammer Specification

- Grain Type

- Synthetic Diamond

- Hardness

- High (Optimized for Stone Processing)

- Backing

- Heavy-Duty Steel Support

- Bonding

- Metal Bonded

- Chemical Composition

- Diamond, Steel, Metal Alloys

- Shape

- Roller/Disc Type

- Toughness

- High Toughness for Extended Usage

- Material

- High-Quality Diamond Segments and Metal Base

- Type

- Bush Hammer

- Grain Sizes

- 30# to 120# (Available as per demand)

- Rolls Size

- Customizable as per requirement

- Strips Size

- Varied per design; standard 5mm-40mm

- Working Method

- Wet & Dry Use

- Packaging

- Box or Carton as required

- Application

- Surface texturing, bush hammering, anti-slip, and roughening concrete, granite, marble

- Connection Type

- Quick-Change, Threaded, or Tailor-made

- No. of Pins/Teeth

- 16, 30, 45, or customized

- Grit Type

- Coarse, Medium, Fine

- Compatibility

- Floor Grinder, Hand Grinder, Automatic Polishing Machines

- Lifespan

- Long service life (varies by usage and application)

- Heat Resistance

- Excellent

- Diameter

- 100mm, 125mm, 150mm, or as customized

Diamond Bush Hammer Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- New Delhi,India

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 3-7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- We use carton boxes for packaging. Wooden crate packaging is at extra cost.

- Main Export Market(s)

- Central America, North America, Eastern Europe, Western Europe, Middle East, Africa, South America, Asia

- Main Domestic Market

- All India

About Diamond Bush Hammer

Diamond Bush Hammer is a construction tool widely used for texturizing as well as renewing the concrete. This is widely used in different kinds of grinder from simple hand-held to electric machines. It is designed using high-grade material with of conical or pyramidal carbide tips. This is ideal for creating a rough texture on the stones to give a look of naturally weathered rock.

Specifications:-

Bush Hammer

1.Center water feed

2.Used for stone surface dressing

3.For granite ,marble ,sandstone and engineered stone

Versatile Surface Preparation Tool

Engineered for multiple surface applications, the Diamond Bush Hammer efficiently textures, roughens, and creates anti-slip surfaces on concrete, granite, and marble. Its high-quality diamond segments ensure consistent performance and a long lifespan, even in demanding environments. Adaptable for both wet and dry use, it fits various machinesfrom floor grinders to hand grinders and automatic polishersmaking it an ideal choice for diverse stone processing tasks.

Customizable for Your Needs

Pick from a wide range of pins/teeth (16, 30, 45, or custom), diameters (100mm, 125mm, 150mm), grit sizes (30#120#), and connection types (quick-change, threaded, or tailored). This bush hammer also offers options in strip sizes, shapes, and packaging, ensuring it meets specific requirements for distributors, importers, and contractors. Its heavy-duty steel backing and advanced metal bonding provide additional durability for extended use.

FAQs of Diamond Bush Hammer:

Q: How can the Diamond Bush Hammer be used for surface texturing and anti-slip treatment?

A: The Diamond Bush Hammer is specially designed for creating textured, roughened finishes and anti-slip surfaces on concrete, marble, and granite. It operates efficiently with both wet and dry use, making it suitable for a variety of job site conditions and safety requirements.Q: What types of machinery are compatible with this bush hammer?

A: This bush hammer works seamlessly with floor grinders, hand grinders, and automatic polishing machines, thanks to its versatile connection options including quick-change, threaded, or tailor-made adapters. Just ensure the diameter and connector match your machines specifications.Q: When is it best to use coarse, medium, or fine grit bush hammers?

A: Coarse grits are ideal for aggressive surface roughening or removing heavy coatings. Medium grits suit moderate texturing tasks while fine grits are perfect for lighter, more detailed surface finishes or preparing stone for further processing. Select grit according to the desired finish and material hardness.Q: Where can this bush hammer be applied for optimal results?

A: For best results, use the bush hammer on flat, accessible concrete, granite, or marble surfaces such as industrial floors, walkways, and stone panels. Its adaptability to both indoor and outdoor settings makes it valuable for various construction and restoration projects.Q: What benefits does a synthetic diamond bush hammer offer in terms of durability and heat resistance?

A: With high-quality synthetic diamond segments and a robust metal bonded base, this bush hammer exhibits excellent toughness and heat resistance. It can withstand long hours of operation without significant wear, ensuring a prolonged lifespan even under intensive usage.Q: Can this bush hammer be customized for specific industrial applications?

A: Absolutely. The Diamond Bush Hammer is available with customizable pins, diameters, grit sizes, connection types, and packaging. This makes it suitable for different industry sectors, whether youre a distributor, contractor, or manufacturer requiring tailored solutions in India.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Grinding/Texture Abrasives Category

Grinding Accessories

Minimum Order Quantity : 1 Piece

Type : Grinding Accessories (Rolls & Strips)

Toughness : High

Shape : Rolls, Strips

Chemical Composition : Varies depending on abrasive type; typically Al2O3 or SiC

Backing : Cloth, Paper, or Polyester

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free